You can see detailed information by clicking on the name of each equipment.

|

Equipment name | X-Ray Fluorescene (XRF) |

| Use | Projects x-ray on the sample’s surface and conducts qualitative and quantitative analysis using the intensity of fluorescent x-rays generated |

|

|

Equipment name | X-Ray Diffractometer (XRD) |

| Use | Projects x-rays on the crystalline sample and measures the inter-facets distance, which is a specific constant of each material, using x-rays diffracted so as to identify the crystalline materials based on the result |

|

|

Equipment name | Inductively Coupled Plasma Spectrometer (ICP) |

| Use | Conducts qualitative and quantitative analysis of atoms by measuring luminescence lines and strength of cation |

|

|

Equipment name | Scanning Electron Microscope(SEM/EDS) |

| Use | Project electronic beam on the sample surface and measures the wavelength and strength of fluorescent x-rays generated to analyze types and content of elements of the sample |

|

|

Equipment name | Particle Size Analysis |

| Use | Projects He-Ne Laser Beam on the cells where the samples are distributed and detects the diffracted light with photodector to measure the size of particles |

|

|

Equipment name | TG/DTA |

| Use | Heats up the sample and analyzes changes in its state (e.g. changes in weight or calories) by comparing it to alumina reference |

|

|

Equipment name | Dilatometer |

| Use | Measures the expansion/contraction rate of the sample by increasing the temperature from the room temperature to the target temperature |

|

|

Equipment name | Carbon Analyzer |

| Use | Measures the amount of free carbon and combined carbon contained in refractories | |

|

Equipment name | Thermal Conductivity Tester |

| Use | Measure thermal conductivity of refractories | |

|

Equipment name | Tester of Refractoriness under Load |

| Use | Measures deformation of refractories under load at a high temperature | |

|

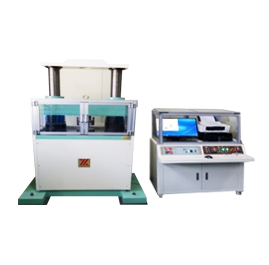

Equipment name | Compression Tester |

| Use | Measures strength of refractories under load | |

|

Equipment name | Modulus of Rupture Tester |

| Use | Measure flexural strength of refractories under load | |

|

Equipment name | Hot Modulus of Rupture Tester (Vacuum) |

| Use | Measures flexural strength of refractories under load at a high temperature | |

|

Equipment name | Refractory Tester |

| Use | Measures refractoriness of refractories by comparing refractory sample to seger cone (SK), the standard sample |

|

|

Equipment name | Abrasion Tester |

| Use | Projects SiC on refractories at a constant pressure and measures the volume of surface area damaged by abrasion |

|

|

Equipment name | Spalling Tester |

| Use | A tester to measure sudden expansion or contraction of refractories, which leads to peeling, by exposing them to rapid temperature rise or drop |

|

|

Equipment name | Super High Temperature Vacuum Furnace |

| Use | A super high temperature(~2100℃) vacuum furnace for sintering of refractories | |

|

Equipment name | Rotating Erosion Testing Apparatus |

| Use | A pilot test equipment for predicting the lifespan of refractories, which helps observe erosion resistance and structural spalling of molten steel |

|

|

Equipment name | High Speed Mixer |

| Use | Large-capacity heating mixer | |

|

Equipment name | Infrared Thermal Camera |

| Use | A camera that detects temperature distribution of the furnace body to assess remaining refractories |